A clothing tech pack is a crucial part of the fashion design development process, but not everybody gets their technical packs right.

Partly that’s because first time designers see the word “technical” and panic. Clothing tech packs do involve technical elements like correct garment dimensions and language specific terminology, but they’re not scientific levels of technical and even the language makes things easier once it’s explained.

In this blog I’m going to break down how to make a clothing tech pack step-by-step for new designers, and curious designers alike.

What is a tech pack and do I need one?

WHAT IS A TECH PACK?

Before we dive into one how to create tech packs, let’s start by defining what a tech pack is! Clothing tech packs, or technical specification packs as they’re sometimes terrifyingly called, are basically the blueprints of your garments.

You wouldn’t build a house without having a blueprint that details the dimensions, floorplan, materials, etcetera etcetera and the same applies to developing clothing.

Without a detailed tech pack, manufacturers can’t accurately quote for your clothing or even correctly produce your clothing. A tech pack acts as a collection blueprint for manufacturers, offering all the design details they need to create your garments in line with your specifications.

Manufacturers need to see every minute detail to be able to calculate production costs, MOQs (Minimum Order Quantities) and to estimate how long the entire product development process will take.

Do I need a tech pack?

I’ve broken this down into a question all by itself because the answer is always: Yes!

Clothing tech packs are the most important asset you have when approaching clothing manufacturers for help producing your ground-breaking new garments.

To give you an overview from a manufacturing point of view, clothing tech packs help:

Assess what style of clothing the technical designer is producing. Depending on the style the designer is using, a factory-ready tech pack determines a number of other factors such as how complex the manufacturing will be, the estimated timeframe of the work, and the estimated cost.

Calculate how much fabric needs to be cut. By using seam-to-seam measurements, manufacturers can calculate how much fabric needs to be used to produce the garments which is vital for costs and accurate production.

Calculate the costs of materials. Every tech pack has a BOM (Bill of Materials). These help manufacturers to calculate how much materials and accessories will cost, such as buttons, zippers or sequins. Manufacturers need to know this information because they source these accessories using MOQs from their suppliers, which often come in the hundreds and thousands, so no manufacturer wants to have thousands of teal sequins laying around if your garments only needed five.

Get the colour right. In a tech pack the colours of the garments will align with something known as the Pantone Code. The pantone code refers to the Pantone colour matching system, which is seen as the leading authority on accurate colour matching. More on that later, but using this code will help manufacturers make your colours vibrant green instead of moss green.

Determine dyeing costs. If a manufacturer doesn’t have your colour, it will need to be dyed using either natural or conventional dyes. This does come at a cost, and so will need to be incorporated into the overall costs of production.

Determine printing techniques. Depending on the prints your garments will have on them depends on the printing technique. Some techniques work better for larger prints because they don’t condense the image or colour, and some work better for smaller prints to enhance the colour. Manufacturers therefore need to assess your artwork files to work this out, so the correct technique can be used without compromising the image quality.

Provide specifications of care labels. The possibilities and options from suppliers regarding care labels, woven labels, or even hang tags, are endless so manufacturers need a spec sheet in order to tell the designer the MOQs and calculate the costs.

Ensure quality control. By having a tech pack with all of your measurements, materials and specifications, manufacturers can check the garments against this list during their quality control process. Quality control planners work to ensure that each garment meets your expectations before it’s shipped out, which makes your tech pack important.

With so much more: As well as the above clothing technical packs also provide information about pattern making and sample production costs, as well as a host of other things.

What should be included in a tech pack?

Now we’ve emphasised the importance of clothing tech packs (very) in the fashion industry, it’s time to move onto how to put together your own professional tech pack.

Ultimately each pack will look different because every garment is individual, and so the prices of manufacturing and production will be too, but to produce a clothing tech pack you generally should follow the below steps.

An idea of the clothes you want to produce

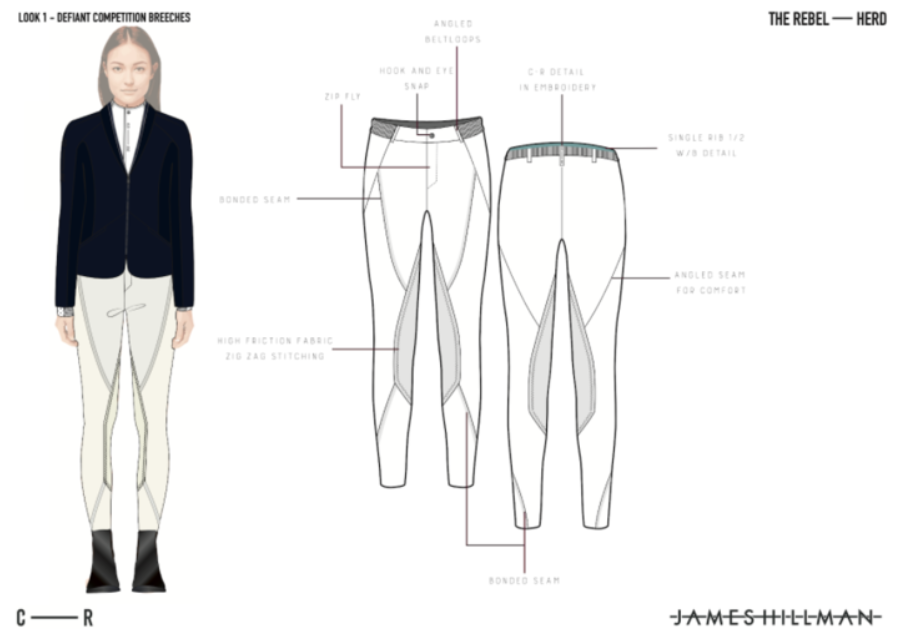

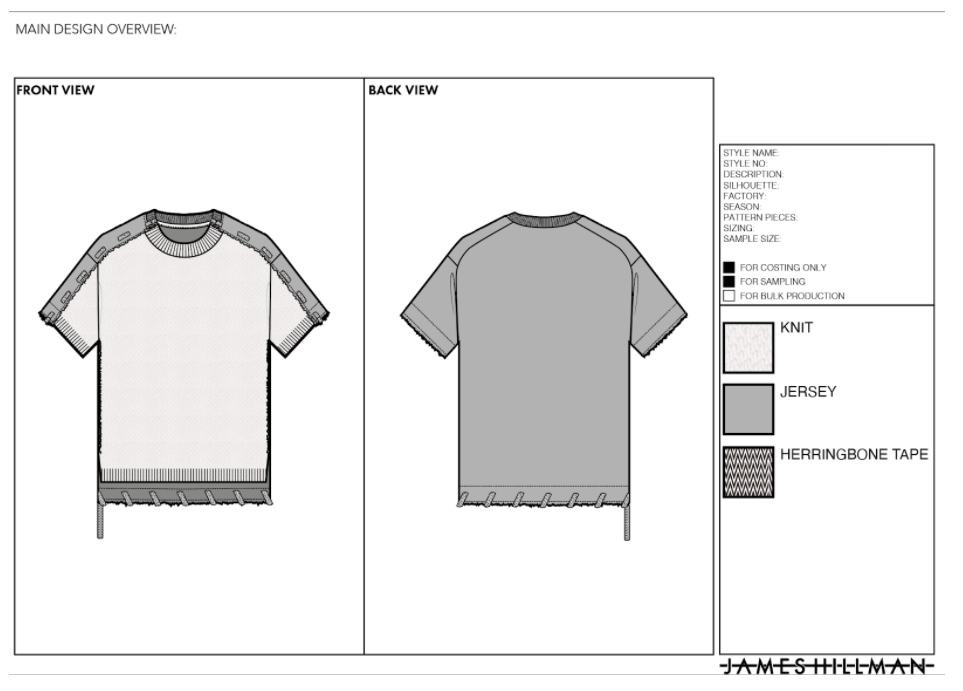

The first and most important step. Just like how this blog has an introduction, so should your tech pack and clothing tech pack introductions tend to be visual! They’re usually a variety of sketches or inspired photographs that give the manufacturer an idea of your end product.

Read more about finding your inspiration by getting comfortable with concepts.

In the introduction your manufacturer will also want to know whether you’re looking to use sustainable materials, natural dyes, or high-end market niche materials to produce the garments.

Further, in your sketches it is helpful to manufacturers to highlight specific finishing and construction detail actual measurements. These pieces of information help to accentuate the specifications of the designs (as displayed in our tech examples below).

There are also different advisory steps to take depending on whether you’re including photographs of inspirational styles, or whether you’re including sketches.

If you’re including photographs make sure you:

Find images as close to your idea as possible, using Google or other search engines.

Save them into your tech pack, with a one-line explanation or annotation if you like.

Use a file compressing tool. If you add large images your file size will jump up, making the overall size of your tech pack too large to email or download in some cases.

If you’re including sketches, make sure you:

Keep them simple, at this stage an overload of information isn’t necessary. You can go into more detail later on.

Use basic shapes with simple elements, which will at this stage just serve to represent the garments features, placement and shapes.

Show the clothing from a straight on angle, no sides yet.

Keep them more detailed than artistic. Remember that they’re a blueprint and not a life drawing class.

We use Adobe Illustrator as it is the best way to develop technical drawings of clothing which is clear, accurate and understandable

It's also worth bearing in mind that just like any introduction, it should be the front or cover page of your tech pack.

And don’t worry, for those who may not have extensive knowledge about garment construction we can recommend a book by FASHIONARY called FASHIONPEDIA. It’s an amazing resource for both new and experienced designers - even we still use it from time to time!

Example of a tech pack

2. Your MOQ

MOQs mean Minimum Order Quantities and every single manufacturer and the suppliers that supply manufacturers has one.

Manufacturers need to know your MOQs and especially your target price to know if your order is worth their while. On average a manufacturer will have a minimum order of perhaps 30 garments, but this figure alters depending on the size of the manufacturer.

If your order is below their MOQ, it just isn’t worth the manufacturer getting involved because the time, cost and labour spent isn’t profitable for their bottom line. It’s harsh, but it’s business.

MOQs also matter for manufacturers because they need to know how your order is spread out across sizes. This is because manufacturers need to know how much fabric and material to order, and no manufacturer likes stocking a lot of it. Why? Because it’s costly, it takes up a lot of room, and your manufacturer will need to contact their supplier who will also ask them, you guessed it, their MOQ.

Away from materials and fabrics, if there’s dyeing involved then your manufacturer is also going to need to buy and then mix a certain amount of dyes to achieve your desired colour. A certain amount of dye will only produce a certain amount of clothing, so this has to be accurate.

Without highlighting your MOQs in your clothing tech pack, manufacturers will fail to identify the best options to make your garments and are likely to pass up working with you. To enhance your chances, make sure you include your MOQs (90 t-shirts, 30 handbags) as well as your sizes (30cmx50cm, etc) so that manufacturers can begin doing their own calculations.

Just getting started in the world of fashion? Read our step-by-step guide as to how to start your own fashion brand here.

3. A list of fabrics & materials you want to use (Your BOM)

BOM is another semantic of the fashion world and it stands for Bill of Materials. Your BOM is just that: It’s a list of the materials you’ll be using to produce your garments.

A common misconception is that designers must know every fabric and composition they’re going to use, and whilst yes, this helps - it’s not a requirement. Designers just need to be able to highlight some type of fabric in their tech packs because manufacturers require a starting point.

For someone that doesn’t know the type of material or composition, a starting point could be as simple as “Cotton that is thick and designed for winter wear”. Alternatively if someone didn’t understand the technical details or the fabric, they could also send a swatch of the fabric to the supplier to source, or speak to fabric mills who could then send swatch samples directly.

If you do know your materials, fabrics and compositions however, make sure you highlight these in the pack.

BOMs also extend to include features like zippers, buttons, trims, tassels, sequins, jewels and any other type of functional material.

Because there are many types of zipper (you’d be surprised) it’s best to accompany your BOM with pictures wherever possible. These can be taken from Google, as long as they’re clear and show the type of functional material you’re going for. Then accompany them with a description of what they are, and where they will go on your clothing. This should be done for any material or embellishment to create a comprehensive tech pack.

4. Your Pantone Code

Step four fills in the colours whereas previously all you’ll have done is made the outlines. Pantone has long been hailed as the world’s leading authority on colour matching, and so in a tech pack, colours should be included following the Pantone Code.

To find your pantone code, just click here, adjust the colour finder palette or enter the name of your colour and hit search. That will give you the corresponding code that you can then submit into your tech packs.

If you’ve found a colour through a search engine, then you need to screenshot the image, include the image in your tech pack and then alongside it write the name of the colour you searched, i.e: Ruby red. This helps manufacturers pinpoint shades and variations.

The same rules apply around any embroidery you’d like to add. With embroidery, if your artwork is going to be specifically placed on your clothing then this must be specified by indicating the exact position of the artwork and its dimensions.

5. Your seam-to-seam measurements

Step five is of crucial importance because it’s time to get specific with seam-to-seam measurements, a make or break decision between your garment fitting well, and fitting not so well.

Seam measurements help manufacturers do two things. Firstly they help manufacturers to calculate how much fabric, material, and dye is going to be used to create the garment which helps them to calculate the dyeing and printing costs.

Secondly, once the patterns are in production the manufacturer will use measurements from your tech packs to create clothing that is custom fitting to your requirements. If the measurements are correct, the fit will be correct.

Seam-to-seam measurements work as part of the sampling process and it’s important that designers understand that things won’t always work the first time in this phase. Depending on how complex the clothing is to manufacture there may be tweaks that do not become apparent until the first fit sample and prototype of the garment is made.

Additionally there are other things to be aware of in the sampling process. If you’re printing a fabric, a Print Strike-off must be conducted. A Print Strike-off is where a manufacturer will print on a 50cm x 50cm piece of fabric to test the print quality. If you want your samples to increase in size, you’ll need to make new samples from your new measurements because a manufacturer can’t just add more fabric.

The sampling process will test your patience but it is worth it. In this process you’ll soon realise how accurate your measurements are, and get a good feel for your product which will enable you to make any necessary adjustments.

6. Info about your brand identity

In step 6, it’s time to make it all about you. If your garments are going to go on to be sold, it’s time to add your branded labels and/or your swing tags.

For all fashion brands, it's important to include your labels or tag designs within your clothing tech pack from the beginning, as there are additional costs for these. It’s also essential that designers mention where to place them on the garment.

Swing tags especially will vary in pricing depending on the supplier because there are a plethora of different options available. Swing tags also have the added feature of an eyelet and a choice of material which they will swing from, which can give you unexpected additional costs.

When including information about your brand labels or your swing tags make sure that you make these as detailed as possible. Draw the design out if possible and annotate it with a host of information such as the type of card, the imagery, the extra material.

Your manufacturer will also be looking to know the dimensions of your label, the positioning on your clothing, the fabric and colour of your label, as well as any imagery or embroidery. Indicate all of this information on the drawings you provide.

Find out how to develop your fashion brand identity here.

7. Your final checklist

That’s it, you’re nearly done! If you’ve followed the previous six steps your tech pack should so far include your introductory images or sketches, your MOQ, information about your fabrics and BOM, your colours in accordance with the right pantone code and information about your brand identity. Before making sure that your tech pack is ready to go, use this checklist to make sure that everything is presented as it should be.

If your checklist has a tick in every box, congratulations! You now have a clothing tech pack that’s ready to be sent to your desired manufacturer and that will hopefully transform your ideas into garments!

The tech pack is in a clear and understandable format that a manufacturer can easily understand.

The tech pack has an introduction page that shows various images or sketches of the desired end garment

Your tech pack contains your Minimum Order Quantities and your sizing breakdowns

Your tech pack includes information regarding your desired fabric choices

Your tech pack includes information about your garments colours that are in accordance with the Pantone code

Your tech pack includes the correct examples and specifications regarding any printing or embroidery

Your tech pack includes the correct seam-to-seam measurements for each article of clothing

Your tech pack includes examples and specifications of your care labels, brand labels and/or swing tags

If your checklist has a tick in every box, congratulations! You now have a clothing tech pack that’s ready to be sent to your desired manufacturer and that will hopefully transform your ideas into garments!

In summary:

Tech packs may sound complex but they’re not. Once you’ve broken down each stage and made sure that your garments have specifications, examples and annotations to help your manufacturers the process becomes easier. The more tech packs you create the more you will get comfortable with them, and eventually you’ll know the right amount of information to include.

At James Hillman we’ve been creating clothing tech packs as part of our design development services for years. We know they can be tough to get your head round, and that’s why we’re always happy to lend our expertise so that we can make the journey from idea to production as seamless as possible. For more information about how we can help your fashion brand, why not get in touch with us today?